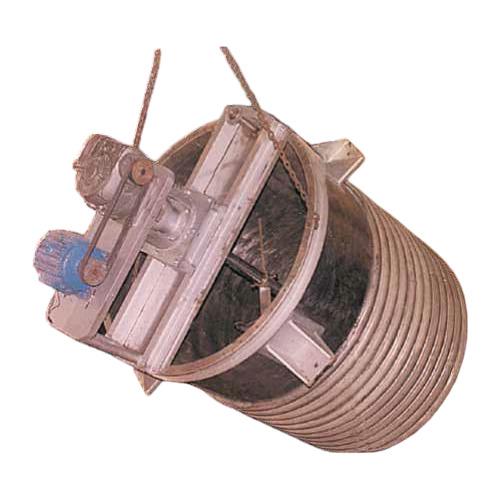

Jacketed Reaction Vessel

Price 100000.00 INR/ Unit

Jacketed Reaction Vessel Specification

- Usage

- Industrial

- Material

- Stainless steel

- Size

- Standard

- Condition

- New

- Color

- Green

Jacketed Reaction Vessel Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

- Certifications

- ISO : 9001 , 2008

About Jacketed Reaction Vessel

Jacketed Reaction Vessel

Designed and manufactured to perfection, our company is considered as one of the renowned manufacturers and suppliers of Jacketed Reaction Vessel. At our premises, we are manufacturing vast range of reaction vessel for our widespread clients. Offered Jacketed Reaction Vessel finds wide usage in chemical industry and several other areas for different chemical experiments. These reaction vessels are well recognized in the market for their distinctive features such as robust construction, negligible maintenance and impeccable performance.

TECHNICAL DETAILS

JACKETED REACTION VESSEL: JACKETED Vessel can be made of Mild Steel or Stainless Steel as per the application of the user.

Drive System is specially Designed for Maintenance & Trouble

Free Performance.

Lenton Assembly

Lenton Assembly contains Bearing Housing with TOP Tapered Roller Bearing for High Accuracy and resistance to impact load & vibratory load and Ball Bearing at the bottom for smooth rotation. Stuffing Box is provided with Jacket for Cooling arrangement to give long life to Gland rope. Gland pusher is provided with Gunmetal Bush Bearing thus ensuring Minimized Friction giving longer life to the Gunmetal

Bearing. Bearing Housing and Lenton Assembly are steel Fabricated made from M.S. Plates of suitable strength.

Welding

Welding work is performed by Argon Arc process using Good Characteristic Filler rods on all S. S. Parts. M.S. Parts welding is performed by D. C Arc welding process using suitable electrodes of Advani Oerlikon make.

Jacket Welding

Jacket Closure Ring welding work is performed by using high grade filler rods to withstand closure ring tension.

Stifner Ring

Stifner Ring is provided on Inner Shell of Jacket in between Inner Shell and Outer Jacket to intensify main Vessel and to provide uniform circulation and minimize stagnation of heating or cooling medium.

Finish

All weld joints will be finished from inside and outside, S S. Parts is cleaned from inside and outside. Two coats of primer/ redoxide will be given on M.S. parts from outside.

Testing

Equipments are tested Hydraulically as per design Pressure

Service

Complete after sales servicing is provide by our fully trained and competent engineers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reaction Vessel Category

Top Open Vessel-

Minimum Order Quantity : 1 Unit

Material : Mild Steel or Stainless Steel

Condition : New

Size : Standard

Capacity : 1005000 approx. Ltr

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese