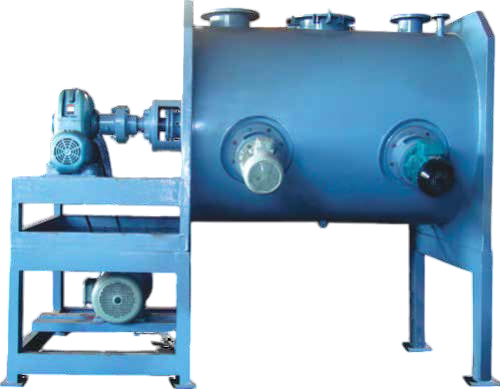

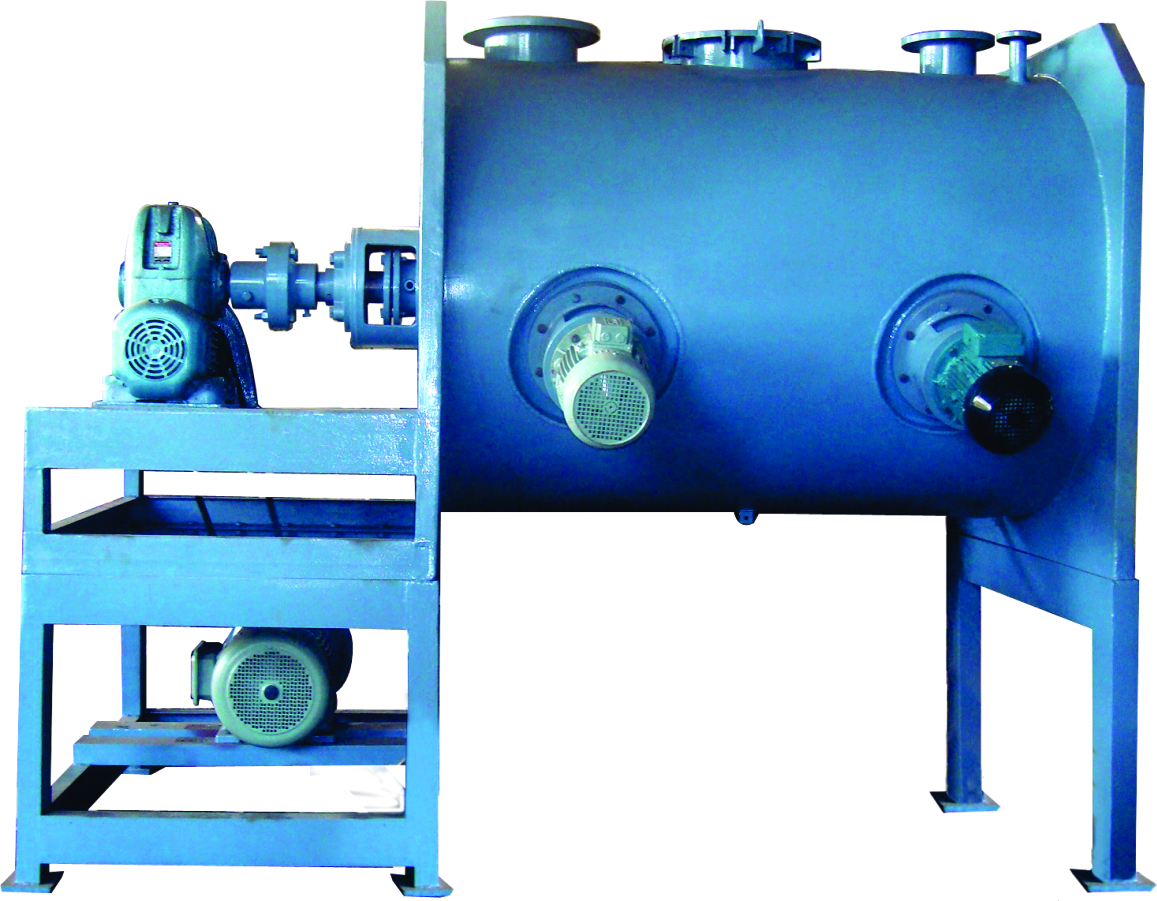

Plough Shear Mixer

Plough Shear Mixer Specification

- Material

- Mild steel & Stainless steel

- Automatic Grade

- Semi-Automatic

- Voltage

- 220-440 Volt (v)

- Frequency (MHz)

- 50-60 Hertz (HZ)

- Warranty

- 1 Year

Plough Shear Mixer Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 4 Week

- Main Domestic Market

- All India

About Plough Shear Mixer

The Plough Shear Mixer by S.S ENGINEERING features a robust, horizontal cylindrical design with flat end plates. The central mixing shaft runs through the axis of the shell, supported by specially engineered bearing housings. Plough-shaped mixing elements are mounted concentrically along the shaft, maintaining minimal clearance with the shell wall to ensure intensive and efficient mixing performance.

Applications

Ideal for mixing and processing across various industries:

- Chemicals

- Minerals

- Food Processing

- Brake Lining & Industrial Gaskets

- Glass Industry

- Animal Feed

- Fire Extinguishing Powders

- Fertilizers

- Dyes & Intermediates

Working Principle

The mixer consists of a cylindrical shell equipped with plough-shaped mixing tools attached to a rotating central shaft. As the shaft rotates, the ploughs create a three-dimensional turbulent motion that facilitates uniform blending, grinding, and dispersion of dry and wet materials.

Choppers, strategically installed between ploughs, enhance the mixing by breaking lumps and improving dispersion. Choppers may vary in design (multi-blade or single-blade) depending on the material and process. They are independently controlled for added flexibility.

Construction & Features

Nozzles

- Feed Inlet: Positioned on the top of the mixer with a quick-opening lid.

- Optional valves include Rotary, Butterfly, or custom types as per the process need.

- Discharge Nozzle: Located at the bottom of the shell. Operated manually, pneumatically, or hydraulically.

- Inspection Doors: Flat-type doors available on the front side for easy access and observation.

Jacketed Design

- Available with or without a jacket for heating or cooling applications, depending on process requirements.

Vacuum/Pressure Compatibility

- The mixer can be designed to operate under vacuum or pressure, enabling solid-liquid-gas phase reactions within the same vessel.

Drive System

- Equipped with a Fluid Coupling between motor and gearbox to:

- Protect against shock loads

- Reduce inrush current at start-up

- Minimize wear on drive components

Control Panel

Includes:

- Independent on/off controls for plough and chopper

- Ammeter and Voltmeter

- Temperature and Pressure Indicators

- Audio-Visual Alarm for process safety

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese