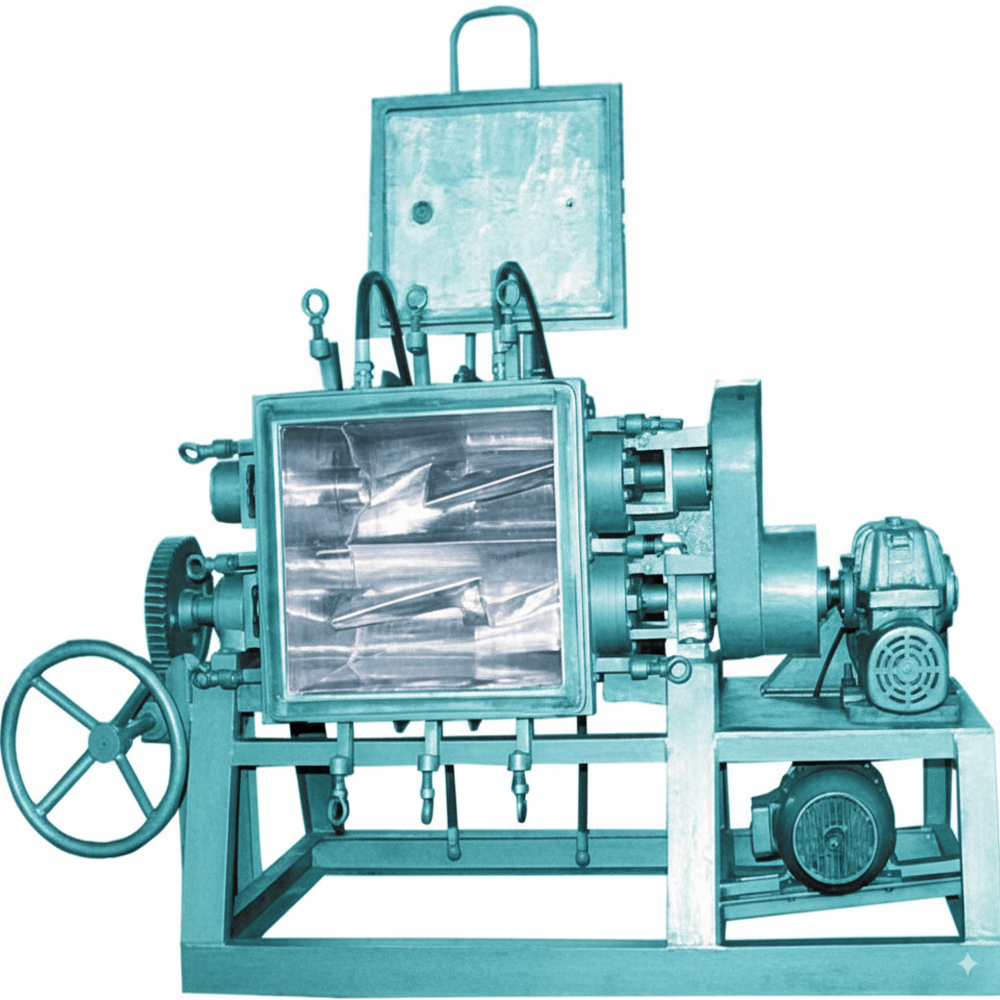

Sigma Mixer

Price 100000.00 INR/ Unit

Sigma Mixer Specification

- Material

- Mild steel & Stainless steel

- Automatic Grade

- Semi-Automatic

- Voltage

- 220-440 Volt (v)

- Frequency (MHz)

- 50 Hertz (HZ)

- Warranty

- 1 Year

Sigma Mixer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 4 Week

- Main Domestic Market

- All India

- Certifications

- ISO : 9001 , 2008

About Sigma Mixer

S.S. Engineering offers a robust and durable Sigma Mixer, also known as a Double Arm Mixer Cum Kneader, designed for intensive operations such as mixing, kneading, grinding, dispersion, and drying of high-viscosity materials. Engineered for long-term, trouble-free operation, it is widely used in various process industries.

Design & Construction:

- The Sigma Mixer features two counter-rotating blades housed in a rectangular trough with a curved bottom (twin half-cylinders) and a central saddle section.

- Blades are driven by a geared motor mounted at one end.

- The mixing container is available in Mild Steel, SS 304, or SS 316, depending on application needs.

- A jacketed structure (in Carbon Steel) is provided for heating or cooling operations.

- Fitted with either a dust-tight cover for standard operation or a vacuum-sealed lid for vacuum processing (optional).

Applications:

Ideal for viscous to highly viscous materials in industries such as:

- Pharmaceuticals

- Adhesives & Sealants

- Food & Confectionery

- Rubber & Plastics

- Paints & Pigments

- Chemicals & Resins

SIGMA MIXER - TECHNICAL SPECIFICATIONS

BLADE DESIGN

The mixing elements are Sigma-type, precision-cast in steel and machined for high accuracy. Two blades contra-rotate inwardly with minimal clearance (12 mm) against the container walls to ensure thorough and uniform mixing.

A Gland Pusher with Gun Metal Bush is provided for each shaft to minimize friction and enhance the service life of the mixer blades.

DRIVE SYSTEM

- Motor Type: TEFC or TEFC Flameproof

- Speed: 1440 RPM

- Transmission: Heavy-duty reduction gearbox (Reputed Make) + Spur Gears with machine-cut teeth

- Lubrication: Grease-lubricated drive assembly with protective guard

DISCHARGE OPTIONS

- Bottom Discharge: For applications where 100% discharge or thorough cleaning is not critical

- Tilting Discharge: for complete discharge and easy cleaning

STANDARD FEATURES

- Manual or motorized discharge for capacities up to 150 Ltrs

- Hydraulic tilting discharge mechanism standard for larger capacities

- Heavy-duty Steel Fabricated Stand for vibration resistance and quiet operation

MIXING ACTION

- The sigma mixer achieves superior mixing through:

- Bulk movement, smearing, folding, stretching, and dividing

- End-to-end circulation via pitched, tangential blades rotating at different speeds

- Enhanced heat transfers due to increased wiped area

- Suitable for solid, liquid, or combined input materials

OPTIONAL - PULL ACTION CLAMPS

- Pull-action clamps using a toggle-lever mechanism allow quick and secure lid fastening. U-bolts offer length adjustment for a firm latch connection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sigma Mixer Category

SIGMA MIXER 200 LTRS

Price 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : S.S. 304, S.S. 316, M.S

Type : SIGMA MIXER

Computerized : No

Automatic Grade : Manual

SIGMA MIXER 100 LTRS

Price 300000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : S.S. 304, S.S.316, M.S.

Type : The 100 L Sigma Mixer is designed for mixing, kneading, crushing, dispersing, grinding, and drying of highviscosity pastes that cannot be effectively processed by conventional powder mixers or liquid blenders. It is widely used in chemical, pharmaceutical, food, and allied industries, offering: Uniform mixing with no dead zones Efficient kneading through dualblade differential speed design Durable construction ensuring product quality and long service life Working Principle The materials are rubbed, pushed, folded, and pressed between the blades and container wall. The material continuously cycles from one end of the impeller to the other. The two mixing elements (sigma blades) are tangent and rotate at different speeds, ensuring thorough kneading. Discharge is carried out by tilting the container through a manual wheel and worm pinion mechanism. Construction Features Contact Parts: Stainless Steel (SS304 / SS316) for product safety and hygiene. Jacket: Provided for heating or cooling applications. Vacuum Design: Available on request, with side glass and light glass for process monitoring. Discharge Options: o Manual tilting with wheel & worm pinion o Screw motorized mechanism o Hydraulic cylinder with power pack o Bottom valve discharge Applications Chemical & Pharmaceutical Industry Silicone resin, sealant, silicon rubber, silica gel Hot melt adhesive, butyl rubber, glass cement BMC / CMC, pigments, plastics, dyestuffs, inks Fiber paste, aluminum silver paste, paper pulp Carbon materials, battery pastes, clay Polyethylene, pitch coating, coal tar pitch, etc. Food Industry Chocolate, dough, bubble gum, chewing gum Soft candy, cheese, and other viscous food products Material of Construction (MOC) Container & Blades: SS304 / SS316 (standard) Optional: Mild steel construction, as per customer requirement

Computerized : Yes

Automatic Grade : Manual

SIGMA MIXER 300 LTRS

Price 700000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : S.S. 304, S.S. 316, M.S

Type : SIGMA MIXER 300 LTRS

Computerized : No

Automatic Grade : Manual

SIGMA MIXER 750 LTRS

Price 8500000.0 INR / units

Minimum Order Quantity : 1 Kilograms

Material : S.S. 304, S.S. 316, M.S.

Type : SIGMA MIXER

Computerized : No

Automatic Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese