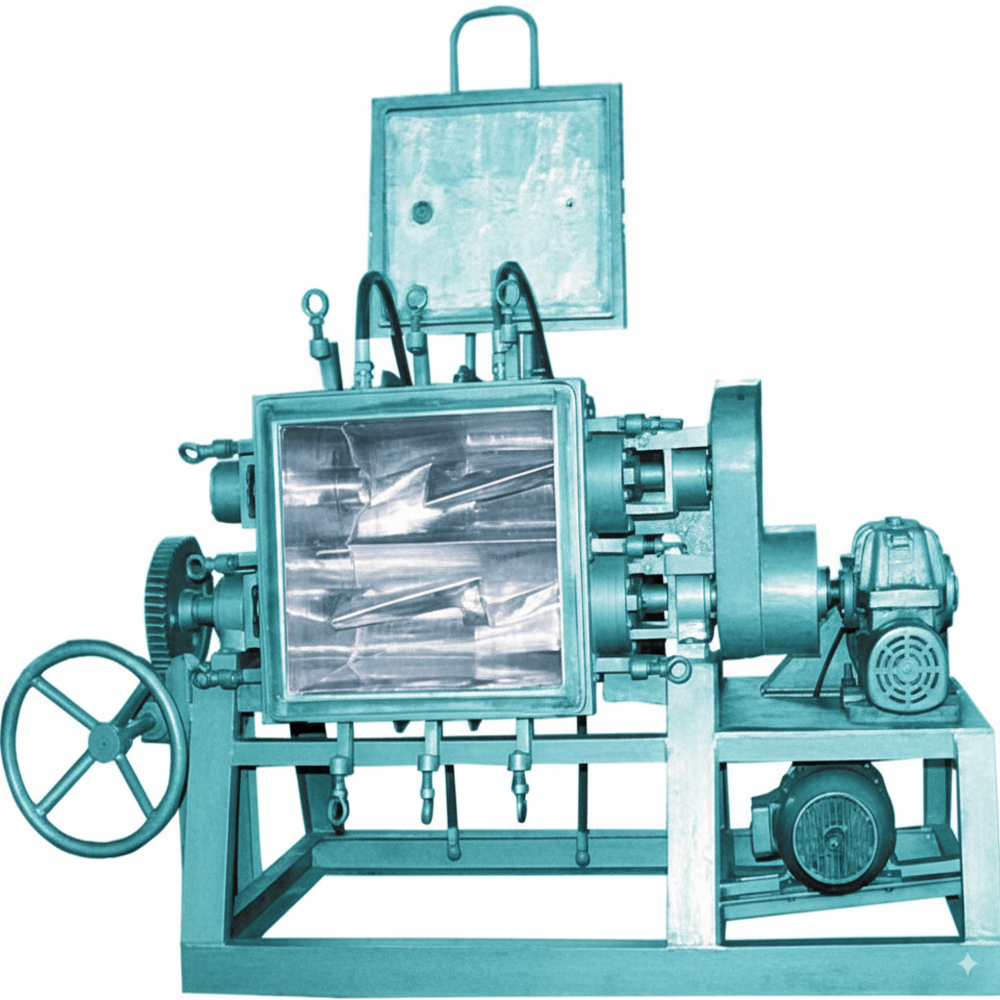

SIGMA MIXER 200 LTRS

Price 600000.00 INR/ Unit

SIGMA MIXER 200 LTRS Specification

- Type

- SIGMA MIXER

- Material

- S.S. 304, S.S. 316, M.S

- Capacity

- 200 Ltr

- Computerized

- No

- Automatic Grade

- Manual

- Voltage

- 440 Volt (v)

- Frequency (MHz)

- 50 Hertz (HZ)

- Width

- 43 Inch (in)

- Weight

- 10000 Kilograms (kg)

- Dimension (L*W*H)

- 2230L*1100W*1570H Millimeter (mm)

SIGMA MIXER 200 LTRS Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 3 Days

About SIGMA MIXER 200 LTRS

The 200 L Sigma Mixer is designed for mixing, kneading, crushing, dispersing, grinding, and drying of high-viscosity pastes that cannot be efficiently processed by conventional powder mixers or liquid blenders.

This equipment is essential for a wide range of chemical, pharmaceutical, and food products, offering:

- Uniform stirring with no dead zones

- High-efficiency kneading due to dual-blade differential speed operation

- Robust design with durable stainless steel contact parts

Working Principle

- Materials are rubbed, pushed, folded, and pressed between the blades and container wall.

- Continuous material circulation occurs from one end of the impeller to the other.

- The two sigma blades are tangent and rotate at different speeds to complete the kneading process.

- Material discharge is achieved by tilting the container via a manual wheel and worm pinion mechanism (other discharge options available).

Construction Features

- Contact Parts: Stainless Steel (SS304 / SS316) to ensure product quality.

- Jacket: Provided for heating or cooling applications.

- Vacuum Design: Optional, with side glass and light glass for process observation.

- Discharge Options:

- Tilting by manual wheel & worm pinion mechanism

- Screw motorized discharge

- Hydraulic cylinder with power pack

- Bottom valve discharge

Applications

Chemical & Pharmaceutical Industry

- Silicone resin, sealants, silicon rubber, silica gel

- Hot melt adhesive, butyl rubber, glass cement

- BMC / CMC, pigments, plastics, dyestuffs, inks

- Fiber paste, aluminum silver paste, paper pulp

- Carbon materials, battery paste, toothpaste, clay

- Polyethylene, pitch coating, coal tar pitch, etc.

Food Industry

- Chocolate, dough, bubble gum, chewing gum

- Soft candy, cheese, and other viscous food materials

Material of Construction (MOC)

- Standard: Stainless Steel SS304 / SS316

- Optional: Mild Steel (as per customer requirement)

| Sigma Mixer Capacity, Size of container required Motor and overall dimension | |||||||||||||

| Model | Total | Working | Container Size | REQUIRED MOTOR | Mixer Overall dimension | Open | |||||||

|

| Volume | Capacity | Length(A) | Width(B) | Height (C ) | H.P. | K.W | AMPS | RPM | Length (D) | Width (E) | Height (F) | Lid Height (G) |

| SS-16 | 200 LTR | 160 LTR | 650 mm | 600 mm | 600 mm | 15 H.P. | 11 | 20.8 | 1450 | 2230mm | 1100mm | 1570mm | 900mm |

| 26" | 24" | 24" | 20 H.P. | 15 | 28 | 1455 | 87" | 43" | 61" | 35" | |||

| For Container Size and Overall dimension please refer Drawing No. SM-1 | |||||||||||||

| Container Size : -Container Length (A), Container Width (B), Container Height (C),Mixer Overall Dimension :- Length (D), Width (E), Height (F), Lid Height (G) | |||||||||||||

| THE FOLLOWING CHART DEPICTS STANDARD MODELS AVAILABLE. BECAUSE OF THE CONTINUING EFFORT TO IMPROVE OUR PRODCUTCS, SIZE AND DIMENSIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. | |||||||||||||

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sigma Mixer Category

Sigma Mixer

Price 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hertz (HZ)

Material : Mild steel & Stainless steel

Automatic Grade : SemiAutomatic

SIGMA MIXER 300 LTRS

Price 700000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hertz (HZ)

Material : S.S. 304, S.S. 316, M.S

Automatic Grade : Manual

Type : SIGMA MIXER 300 LTRS

SIGMA MIXER 100 LTRS

Price 300000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hertz (HZ)

Material : S.S. 304, S.S.316, M.S.

Automatic Grade : Manual

Type : The 100 L Sigma Mixer is designed for mixing, kneading, crushing, dispersing, grinding, and drying of highviscosity pastes that cannot be effectively processed by conventional powder mixers or liquid blenders. It is widely used in chemical, pharmaceutical, food, and allied industries, offering: Uniform mixing with no dead zones Efficient kneading through dualblade differential speed design Durable construction ensuring product quality and long service life Working Principle The materials are rubbed, pushed, folded, and pressed between the blades and container wall. The material continuously cycles from one end of the impeller to the other. The two mixing elements (sigma blades) are tangent and rotate at different speeds, ensuring thorough kneading. Discharge is carried out by tilting the container through a manual wheel and worm pinion mechanism. Construction Features Contact Parts: Stainless Steel (SS304 / SS316) for product safety and hygiene. Jacket: Provided for heating or cooling applications. Vacuum Design: Available on request, with side glass and light glass for process monitoring. Discharge Options: o Manual tilting with wheel & worm pinion o Screw motorized mechanism o Hydraulic cylinder with power pack o Bottom valve discharge Applications Chemical & Pharmaceutical Industry Silicone resin, sealant, silicon rubber, silica gel Hot melt adhesive, butyl rubber, glass cement BMC / CMC, pigments, plastics, dyestuffs, inks Fiber paste, aluminum silver paste, paper pulp Carbon materials, battery pastes, clay Polyethylene, pitch coating, coal tar pitch, etc. Food Industry Chocolate, dough, bubble gum, chewing gum Soft candy, cheese, and other viscous food products Material of Construction (MOC) Container & Blades: SS304 / SS316 (standard) Optional: Mild steel construction, as per customer requirement

SIGMA MIXER 350 LTRS

Price 750000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hertz (HZ)

Material : S.S. 304, S.S. 316, M.S

Automatic Grade : Manual

Type : SIGMA MIXER

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese